WelderDestiny › Welding Engineering Tools › Comparing Heat Treatments

Comparing Heat Treatments

The need for comparing heat treatments often arise when two heat treatments performed at different temperatures and times need to be checked for equivalence. This question is especially pertinent when multiple heat treatment cycles are involved, as the heating and cooling parts of the cycle also have an effect. This is important, because if a Post Weld Heat Treatment (PWHT) cycle is excessive, it can reduce the impact and tensile strength properties. By the same token, if the PWHT cycle is inadequate, it can result in excessive hardness and reduced impact and ductility properties. For this reason, the fabrication codes will generally have limits of qualified PWHT times and temperatures based on those recorded in the Procedure Qualification Record, (PQR) while qualifying the welding procedure. (WPS)

The WelderDestiny Compass: Weekly e-zine Subscription

You can take a look at "The WelderDestiny Compass" back-issues by clicking here.

As

an example, you may have a requirement for a stress relieve Post Weld Heat

Treatment (PWHT) cycle of 600°C for 2 hours, with a 200°C per hour heating and

cooling cycle, but the welding procedure (WPS) you have at your disposal was qualified on 620°C for

1 hour with a 100°C per hour heating and cooling cycle. Would the PWHT on the

WPS be acceptable for this application?

Glowing Electrical Resistance Heating Elements (Also called heat beads) - Normally it will be covered with insulation, so you will not see it glowing.

Glowing Electrical Resistance Heating Elements (Also called heat beads) - Normally it will be covered with insulation, so you will not see it glowing.To

answer this type of question, for comparing heat treatments, Holloman Jaffe parameter calculations are typically

performed.

Please

note that within the context of this discussion, we are comparing tempering or

stress relieving type of heat treatments.

Holloman Jaffe Parameter for Comparing Heat Treatments

Experimentation

and thermodynamic calculations show that the microstructural changes brought

about by thermal heating of materials are exponentially related to the

temperature that is used, but is only linearly associated with time. As an

example, the increased “softening” between using stress relieve temperatures of

600°C and 660°C is much more than just the 10% increase suggested by the rise

in temperature. On the other hand, an increase from 1 hour to 1 hour and 6

minutes (also a 10% increase) will however have a very small effect. When comparing heat treatments, these effects need to be taken into account.

Comparing heat treatments with the Holloman Jaffe parameter only works if we assume that the temperature range we are working with

will not result in an equilibrium phase change. For example, for carbon steels,

the lower critical temperature (Temperature where the ferrite structure starts

changing to austenite.) is typically given as 723°C. We will therefore only be

looking at heat treatment temperatures significantly below this temperature. Please note that this lower critical temperature is higher for alloyed steels.

An

equation was developed to take the heat treatment temperature and time, and

express it as a single number. This number is called the “Holloman Jaffe Parameter.”

By calculating the Holloman Jaffe parameter for each of the heat treatment cycles,

comparing the heat treatments becomes relatively simple.

The Holloman Jaffe Parameter

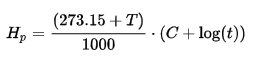

The

Holloman Jaffe parameter for comparing heat treatments is calculated using the following equation:

Where:

- Hp = Holloman Jaffe Parameter.

- T = Temperature in degrees Celsius of the heat treatment.

- t = Time at Temperature in Hours for the holding temperature.

- C = Constant (Unique to each material. For typical carbon and low alloy steels, C = 19.5. Some references prefer 20. When comparing heat treatments, it does not matter what value we use, as long as we are consistent. In our examples we will use 19.5.)

So,

if we know the different stress relieve times and temperatures for different

stress relieve cycles, we can compare them using the equation above.

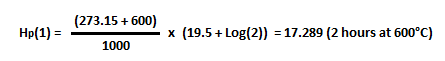

Using

our example above, our first PWHT cycle will give a Holloman Jaffe parameter

of:

Using

our example above, our second PWHT cycle will give a Holloman Jaffe parameter

of:

Comparing

the two heat treatment cycles, we see that the 2 hour cycle at 600°C will

actually have a lesser softening effect on the steel than the 1 hour at 620°C. (The higher Holloman Jaffe parameter indicates greater effect on the steel.)

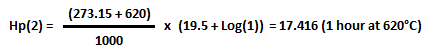

Typical Set-Up for Local Heat Treatment on Pipe Girth Welds. - This is electrical resistance heating with insulation in place.

Typical Set-Up for Local Heat Treatment on Pipe Girth Welds. - This is electrical resistance heating with insulation in place.Accounting for Heating and Cooling Rates

The

one glaring shortcoming in our calculation for comparing heat treatments, is that it does not take

account of the heating and cooling rates. A component heated and cooled at a

rate of 100°C per hour, will surely experience a greater amount of softening

than one that was heated and cooled at a rate of 200°C per hour. There is also

an equation to change the heating or cooling cycle into an equivalent time at

the stress relieve (or tempering) temperature. This equation is as follows:

Where:

- thc = Time in hours calculated to compensate for the heating or cooling portion of the heat treatment cycle.

- T = Holding temperature in degrees Celsius for the heat treatment.

- C = Constant (Unique to each material. For typical carbon and low alloy steels, C = 19.5)

- r = Heating or cooling rate, in degrees Celsius per hour, above 350°C, to the holding temperature.

Let

us apply this equation to our examples above.

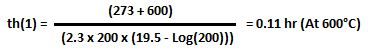

In

the first heat treatment, we had a stress relieve heating rate (r) of 200°C/hr

up to 600°C. This gives us an additional time “th” to compensate for

the heating cycle of:

Our

cooling rate was the same, so we will get the same value for tc(1)

as for th(1). The total additional time will therefore be: th(1)

+ tc(1) = 0.11 + 0.11 = 0.22 hr.

This

means that the total time at temperature will be: t = t(1) + th(1) + tc(1) =

2 + 0.11 + 0.11 = 2.22 hr.

We

can now use this time, and place it into the Holloman Jaffe equation to obtain

a new Holloman Jaffe parameter that takes into account the heating and cooling

parts of the cycle as well.

Our

modified Holloman Jaffe parameter can then be calculated as:

We

note that the value for Hp(1) is now slightly higher, to compensate

for the heating and cooling parts of the cycle.

Let

us do the same for our second heat treatment cycle:

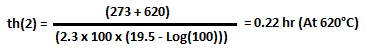

In

the second heat treatment, we had a stress relieve heating rate (r) of 100°C/hr

up to 620°C. This gives us an additional time “th” to compensate for

the heating cycle of:

In

the same way, tc(2) = 0.22 hr.

The

total time to use in the Holloman Jaffe equation then becomes 1.44 hr.

Our

modified Holloman Jaffe parameter for this second heat treatment can then be

calculated as:

Based

on all our calculations, comparing the heat treatments is as simple as just directly comparing the two stress relieve

cycles:

- Hp(1) = 17.329

- Hp(2) = 17.559

This

shows us that the second heat treatment cycle will have a greater effect on the

weldment, even though the time at temperature was half the time of the first

cycle, while the temperature was only increased by 20°C.

Just

something else to keep in mind: Sometimes a component may be subjected to more

than a single heat treatment cycle. This can happen if repairs are required on

a weldment that had already been post weld heat treated, or if the entire

component cannot fit in the furnace in a single charge. Then different sections

of the component may be heat treated separately, with the final “overlapping”

section seeing at least two heat treatment cycles.

These

calculations can obviously become tedious, but they do lend themselves to being

performed on a spreadsheet. You can download an Excel spreadsheet to do these

calculations by clicking here. The spreadsheet allows not only simple comparing of heat treatments, but also allows you to calculate the Holloman Jaffe parameter for multiple heat treatments.

WelderDestiny › Welding Engineering Tools › Comparing Heat Treatments

The WelderDestiny Compass: Weekly e-zine Subscription

You can take a look at "The WelderDestiny Compass" back-issues by clicking here.