WelderDestiny › E-Zine Back Issues › Issue #001

The WelderDestiny Compass

Artificial Intelligence and the Welder - Issue #001 - December 30, 2016

In this edition of "The WelderDestiny Compass":

- Welcome

- Rise of the machines and the commoditization of engineering.

- The rise of artificial intelligence (AI)

- Artificial intelligence and the Welder

Welcome to: The WelderDestiny Compass

In “The WelderDestiny Compass” we will be taking the journey into the future dominated by “the rise of the machines”. The digital age, the information age, the automation age… There are many names for the age we are in. Whatever you call it, the rate of change will just increase, and the uncertainty in our society and jobs will increase alongside these phenomenal changes.

As a welding engineer with over 25 years industry experience I, Niekie Jooste, have made it my mission to assist in equipping Welders for this new era.

A compass will point you in the right direction, but it is not a map. You still need to find the right road to get you to your specific destination. In the same way, “The WelderDestiny Compass” aims to highlight the changes moving towards us in the welding industry, and hopefully position us to move in the right direction. A direction of not only survival, but possibly even profit.

We will be looking at three general areas in the e-zine. The first we can categorize as “principles” or “theories”. In this section, we take a broad look at what is happening in the world, and how “the world works”. The second topic is “technology”. In this section we will discuss current technological trends and developments that can significantly impact our society and lives. The third topic is “application”. In this section we will consider how the discussions of the other sections could impact our jobs within the welding industry. In particular, the job of the Welder.

Rise of the Machines and the Commoditization of Engineering

A number of companies are on the cusp of bringing out self-driving cars and trucks. (The estimate for when this technology will “go mainstream” is about 5 – 10 years.) This sounds all science fiction like. You can picture in your mind how you go outside to your car, and tell it where you want to go. Then it takes you there while you finish applying your make-up or reading through your presentation, or whatever. In the bigger scheme of things, this picture is not that different to what we already have today. The only difference is that you do not have to do the driving yourself. But is this really how things will work in a world of self-driving cars?

Let us for a moment think about “ride sharing” services like UBER. Now imagine that instead of a car with a driver coming to give you a lift when you "hail a ride", a driverless car pitches up to give you a lift. What implications will that hold for the entire transport industry?

How easy will it now be for individuals to purchase a dozen or so driverless cars and have them shuttle people around a city day in and day out, using Uber as their business platform? How long will it take for people to realise that they probably do not need a car for their day to day transport needs, because there will be over enough driverless cars waiting around to take them wherever they need to go? How will this impact the business model of car hire companies? How will this impact the business model of public transport companies? (Busses, trains etc.) Obviously it will be diabolical for "professional drivers" such as taxi drivers and limo drivers.

If the default way of getting around cities is to just hail a driverless car, rather than families using their own multiple cars that stand idle 80% of the time, then the productivity associated with cars will skyrocket. How will this impact the volume of cars sold by automobile manufacturers? The demand for higher end cars may totally collapse, if you have no real control over how luxurious the car will be that pitches up to give you a lift. Probably the only cars that private individuals will buy are those that confer extreme status such as sports cars, or specialist vehicles associated with specific pastimes, hobbies or jobs. How will this whole picture impact the business model of companies supplying parking lot services in cities? How will this impact companies operating toll roads?

Considering the picture painted above, it becomes clear that the whole process of changing the basic transport paradigm will result in huge shifts of economic rent. (We will be addressing the concept of economic rent in a near future edition of “The WelderDestiny Compass”, so stay tuned!) There will be totally new industries established, and some industries or business models will be decimated.

While we have explored just one of the paradigm shifts that could totally change our world, (driverless cars) these paradigm shifts created by "the rise of the machines" will be everywhere.

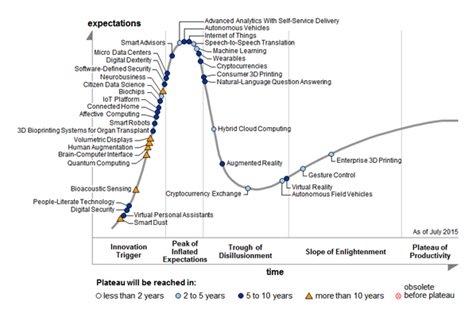

Below is a graphic showing some of the anticipated technologies and estimated time frames till they become "mainstream", as described by the researchers at Gartner. (This is their "hype cycle" research, so it also gives us their take on the psychology of the introduction of new technologies. - Make of that what you may!)

The changes will not happen overnight. They will be slow and novel at first, but before we know what has happened, our world will be unrecognisably changed. So, what can we expect for the engineering industry as a result of the "rise of the machines"? We believe that the biggest foreseeable change will revolve around “the commoditisation of engineering.”

In earlier, gentler times, those of us in engineering tended to see everything in terms of "creative input" to solve new problems. Every new problem required at least a new solution, if not an actual novel solution. This approach has been steadily changing over the past decade or two. Now a lot of engineering is the application of "modular" solutions.

You want an LNG plant? Sure, we will design it in India, based on our proprietary technology, then build the modules in China and assemble it on site wherever you want it. Even this approach takes a lot of engineering manpower, with thousands of engineers needed to generate the necessary construction drawings and perform the necessary purchasing functions etc. to get to a point where an operating plant is standing. It also takes thousands of artisans to build the necessary equipment and install it as required. Once we reach the final stages in the commoditisation of engineering, things will look significantly different.

To build the same LNG plant we discussed previously, the necessary process design parameters will be entered into a computer. (The composition and flow rates expected from a gas field, along with the necessary geospatial and geological information.) The computer will then do the process design for the plant with minimal human input. Once the process design is done, it will use those as inputs to do the equipment design and instrumentation design needed to control the plant. All this information will reside in a giant computer model. (OR in a number of computers running in parallel, solving different parts of the problem.)

Within hours, a cost estimate and 3D model for a plant will be ready for evaluation by the relevant investors and authorities. Any of the equipment design information can then be fed into the production systems of the workshops that will manufacture the necessary equipment. (Obviously "off-the-shelf" equipment such as standard sized pumps and motors will be specified as far as possible in the design.)

A great deal of the equipment will then be manufactured under automated conditions. Many of the components that were previously welded constructions will be made through "additive manufacturing" processes. (3D Printing) In this scenario, the amount of human involvement in the whole design, project management and fabrication process will be cut by maybe 80% compared to that required today.

So, what will the engineers and artisans (tradesmen) be doing in this new paradigm? Mostly they will be "teaching" the machines and computers how to do the work, and then “supervise” the machines and computers. Instead of designing a piping system, the piping engineers will be working in conjunction with the necessary computer programmers to develop the software that allows piping systems to be designed by the computer.

As welding engineers we will be involved with "teaching" the computer how to develop welding procedures and the necessary NDT required to produce the piping systems designed by the computer. The artisans will typically have more of a supervisory capacity over the automated systems to make sure that they can deal with "non-standard" conditions encountered, and to optimise the production process.

Within the paradigm described above, we see that there is actually an escalation in the skills required by the engineers and artisans. Not only will a welding engineer need to know how to develop welding procedures, but also how to interact with software to enable a computer to perform that function.

Not only will a Welder need to know how to weld, (If you do not know how to weld, how can you set the machines properly, or know when something is going wrong?) but will also need to have skills such as computing, metallurgy, codes and inspection. We may ask ourselves if it is really reasonable to expect welders to have all these skills? To answer that question, let us make a short trip down memory lane.

Twenty five years ago, finite element analysis (FEA) was a relatively new tool. It was typically used by specialists in their field. Mostly engineers and scientists with PhD's. Building an FEA model was a rather complicated process, and it was very easy to get it wrong. If you did not know all the fancy mathematics that the computer was using to solve the numerous equations to get an answer, you would in all probability end up with a totally garbage answer. Today the FEA applications are much more powerful and user friendly. Now a reasonably "standard" engineer can do a relatively short course on FEA and do some really amazing stuff. Has the quality of engineers increased that much? No, the quality of the FEA software has increased that much!

This brings us to discussing our next topic today…

The Rise of Artificial Intelligence

While some people think of artificial intelligence in terms of “sentient” robots, I believe this is still rather far off. Some people believe that all we need for sentience is that computing power needs to get as great as that of the human brain. This is projected to occur around 2025 or so. After having read some commentaries by people on the front line of AI research and development, I think that this is a simplistic view of sentience, and that it will take a lot longer to achieve. (If ever)

None-the-less, when we talk about AI here, we are talking about computers that are able to learn and interact with humans in a meaningful way. Using this definition of AI, we can see that we are already almost there.

The “top of the road” AI’s like IBM’s “Watson” are able to learn to solve very complex problems. There are also a number of “mainstream” AI programs such as Apple’s SIRI that is getting to a point where they are able to interact with humans and learn. All the major technology companies are working on AI systems, so this is an area that will be moving rather quickly into the near future.

While AI technology has the potential to replace human workers in just about any job, the easiest jobs to replace are actually knowledge workers. It will also be the most effective use of AI technology, because knowledge work is actually where computers are pretty good, and humans are actually not so good.

My take, is that most people will end up with their own personal AI. This AI will be able to monitor our lifestyles and learn what we like and therefore be able to support us. To see how this could work, let us look at healthcare, as that is a sector that affects us all.

The current healthcare system really is a “generic sick care” system, when you think about it carefully. (We will also discuss this in future e-zines.) Doctors rarely diagnose people, they diagnose illnesses. They do not treat the patient to remove the cause of the illness. The doctor treats the illness by prescribing some pill or other to “compensate” for the symptoms. (A generalization I know, but not entirely inaccurate.) A doctor typically only wants to spend around 15 minutes when we go to see him/her. They also have a living to make, and spending a couple of hours per patient will just not be economically feasible for them.

Now, if we each have our own AI, then when we go to visit the doctor, our AI will talk to the Doctor’s AI, communicating our lifestyle factors to the doctor’s AI. The doctor’s AI will have access to our medical histories, genetic records and any trends in pathology results, and can form a diagnosis and treatment plan. Most of the time, the “treatment” would not necessarily include medicine, but rather recommendations of how to change our lifestyles. Our AI’s will then be our support system to help us follow the recommendations.

The AI will not replace all doctors, but it will mean that far fewer doctors, assisted with AI’s, could more effectively treat many more patients. Now think how such a model could be implemented in almost all “knowledge based” services.

The Welder and Artificial Intelligence

This brings us back to the poor Welder being expected to master all those additional skills. Basically it will be required of engineers to ensure that the Welders not only control the machines, but that Welders themselves will have "machine assistants" to help them.

Now we can already see pictures of ourselves being followed around by an R2D2 lookalike robot (A Star Wars reference, just in case you are not a science fiction fan.) to help us, but that is probably unlikely. Much more likely is the scenario that the Welder will have a portable computing device (think smart phone or tablet computer) with software that can help with supplying the answers.

While we will probably all have “generic” AI’s to help with our everyday lives, professionals in just about any profession will have some kind of “bolt-on” to their AI to assist with their professional responsibilities as well. In this picture of the use of AI’s, Welders will have “welding modules” added to their personal AI to help them. (Somebody is going to have to develop those welding modules.)

While automation under controlled conditions is a cost effective solution, there will still be jobs that are out in the field under conditions where fully automated systems cannot work effectively. These are typically maintenance type environments, or small scale manufacturing where the expense of the use of super computers and massive automated systems would not be warranted.

Within this environment, the use of AI’s by Welders will significantly improve their effectiveness and productivity, and would actually result in such productivity improvements that further mechanization would be uneconomic. This would actually preserve the Welder’s job under those circumstances, rather than being a driver for replacing the Welders. You do however need to be one of the Welders that can effectively work within such a system.

We will delve into this future Welder’s world in more detail in future editions of “The WelderDestiny Compass”.

Yours in welding

Niekie Jooste

WelderDestiny › E-Zine Back Issues › Issue #001

The WelderDestiny Compass: Weekly e-zine Subscription

Do You Have Thoughts About This Week's E-Zine?

Now is your opportunity to contribute to the topics in this week's The WelderDestiny Compass. If you have thoughts or examples that you would like to share with other readers of the e-zine, then please contribute by entering the title of your contribution in the box below. Feel free to make a brief or more expansive contribution to our discussion...

Your Ideas on Artificial Intelligence and Automation

Do you work in an industry where artificial intelligence or automation in general is having a big impact? / Do you have any insights or opinions on the progress of technology on our professional lives? / Please share your stories, insights and even fears or wishes, regarding automation and artificial intelligence, with us.

Read Other E-Zine Contributions

Click below to see contributions from other readers of this edition of The WelderDestiny Compass...

Impact of Technology on Professional Lives

In the industrial landscape, change usually happens slowly enough that it can be seen coming with a fair degree of warning. We can try to prepare for it …