| Back to Back Issues Page |

|

|

The WelderDestiny Compass #047 - Base Metal Thickness November 22, 2017 |

Wednesday, November 22, 2017 / Perth Australia / By Niekie Jooste You can also read this e-zine on the WelderDestiny website by clicking here...

Base Metal Thickness - Issue #047In this edition of "The WelderDestiny Compass":

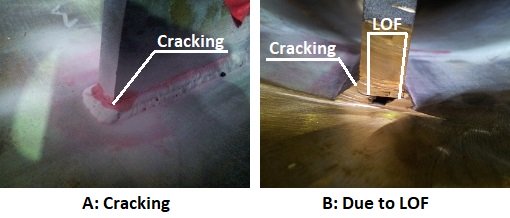

Base Metal Thickness Essential VariableWe have spent quite a number of weeks discussing what the future business organisation might look like. This is important, as it enables us to gain the necessary skills to be effective participants in the machine era.Obviously, as Welders, it is important to sharpen up our welding related skills and knowledge as well, so this week we return to our series on discussing the welding procedure essential variables. Today we look at the base metal thickness essential variable. It is an essential variable in almost every welding code, so it is obviously important. While it may seem like a simple variable, the results while welding is multi-faceted, so it is well worth us spending some time on. If you would like to add your ideas to this week’s discussion, then please send me an e-mail with your ideas, (Send your e-mails to: compass@welderdestiny.com) or add a contribution directly into the comments form on the bottom of the e-zine page on the WelderDestiny website. Click here to add your contribution directly to the WelderDestiny website... Now let's get stuck into this week’s topics... Fusion ImplicationsIf the thermal energy introduced by the welding arc is rapidly removed from the weld, then the amount of base metal melting that occurs will decrease. Under particularly adverse conditions, the heat from the arc can be removed out of the welding area so rapidly that no melting of the base metal occurs. We then get a lack of fusion defect being created.This is particularly evident in welding processes where the heat input into the weld is very low. An example of this is the Gas Metal Arc Welding (GMAW) process when using "dip transfer". (Also called short circuiting transfer.) When welding with the dip transfer mode of GMAW, a lot of the heat goes into resistance heating of the wire, and not so much into the arc. This means that it is quite easy to melt the welding wire without actually melting the base metal. For this reason, most codes limit the maximum base metal thickness qualified to 1.1 times the thickness of the qualification coupon when using the dip transfer mode for the GMAW process. Lack of fusion is also often found when welding alloys with high thermal conductivity such as copper. This can be seen in the figure below.  Cracking found externally as seen in photo "A". This was due to lack of fusion (LOF) in the root of the weld, as seen in photo "B".

Cracking found externally as seen in photo "A". This was due to lack of fusion (LOF) in the root of the weld, as seen in photo "B".

Metallurgical ImplicationsDuring fusion welding, the weld metal and Heat Affected Zone (HAZ) of the base metal next to the weld, undergo phase transformations and other changes to the microstructure. As the base metal thickness increases, the cooling rate of the weld and HAZ also increases.The most obvious phase transformation is a change from a liquid (molten) metal to a solid. During this process, there is a process whereby the molten metal starts to nucleate solid "grains" of crystal, and then these nuclei start to grow, until these grains touch each other. At that point, all the liquid metal will have turned to solid. In other words, solidification is a process of crystal nucleation and growth. The faster this process occurs, the more "grains" there are in the solidified weld. At the same time, the more grains there are, the smaller these grains need to be. In other words, the faster the solidification process, the finer the final grain structure of the weld metal. A fine grain structure has a very pronounced effect on the strength and toughness properties of a weld. Grain refinement is one of the only ways to increase the strength of a metal while also increasing the toughness properties. In the area next to the weld metal, the HAZ, most alloys will also experience phase transformations. These transformations are however solid state transformations. As an example, in the case of ordinary carbon steels, the steel typically changes from a ferrite phase to an austenite phase while heating up, and then the reverse happens when it cools down again. If the cooling rate is quite rapid, then the transformation from austenite back to ferrite can be hampered, because this transformation is dependent on diffusion taking place within the metal. When there is not enough time for the necessary diffusion to take place, then the steel will transform to some intermediate "meta-stable" structure such as martensite. The mechanical properties of these meta-stable phases are significantly different from that of the "equilibrium" phases that would form under lower cooling rates. In the case of martensite, it is a hard and brittle material. In short, during welding, a thin material cools down slower than a thick material, resulting in a coarser grain structure and less meta-stable phases being formed for the thin material. Dilution EffectsDue to the more rapid removal of heat for a greater base metal thickness, the result is that there is a steeper temperature gradient from the molten metal to the "cold" base metal. This steeper temperature gradient means that the amount of base metal being melted is less than when the base metal is thinner.When less base metal is being melted, then the percentage of base metal being added to the filler metal is less. In welding terminology we say that there is a lower dilution of the filler metal by the base metal. This dilution effect is very important in any circumstance where the welding consumable has a significantly different chemical composition from that of the base metal. This is very typical when performing weld overlays. A typical weld overlay may be the deposition of a type 316 stainless steel onto a carbon steel base metal. The greater the dilution of the welding consumable during weld overlays, the more layers of weld metal may be required to achieve the required final chemical composition of the weld overlay surface. For this reason, the base metal thickness is an important essential variable when performing weld overlay, because the thicker the base metal, typically the less the dilution will be. Qualified RangesEvery welding code will deal with the base metal thickness essential variable differently, so there is no single qualified range. We will however discuss the typical approach that different welding codes take to this essential variable.Most welding codes have an upper qualified base metal thickness that is twice the thickness of the qualification coupon. However, once the base metal thickness goes above a certain value, then this heat sink effect tends to stop increasing much. Many welding codes therefore allow the upper qualified base metal thickness to become almost unlimited if the coupon thickness is above this specific thickness. In the case of the ASME IX welding code, if the base metal thickness of the qualification coupon was greater than 38mm, then the maximum thickness qualified is 200mm. The Australian pressure equipment code AS3992 has a very similar approach. In the case of the AWS D1.1 structural steel code, a coupon thickness above 25mm base metal thickness qualifies for an unlimited upper thickness during production welding. The lower thickness qualified varies between different welding codes, but a typical approach is either a half the coupon thickness, or a stepped lower limit based on the coupon thickness. The Australian structural steel code AS 1554.1 limits the lower thickness to half the coupon thickness. The American structural steel code AWS D1.1, limits the lower thickness to 3mm for plates, regardless of the thickness of the test coupon. It is instructive to note that the scope of AWS D1.1 is limited to steel plates thicker than 3mm, so there is no need to deal with thinner materials. ASME IX and AS 3992 give a lower limit of 1.5mm for test coupons up to 10mm thick, and a lower limit of 5mm for a test coupon thicker than 10mm. There is a complication in that the lower thickness is often different when impact test applications are being considered. This is because of the effect of grain growth. As mentioned previously, when the cooling rate is lower due to a lower quenching effect of thinner materials, then there can potentially be a greater amount of grain growth within the weld metal and HAZ. A coarse grain structure will result in a material with less toughness than a fine grained material. The lower thickness is therefore more stringently controlled for impact test applications. If you would like to see a more complete discussion of the base metal thickness essential variable for welding procedures, then please click here...

Niekie Jooste P.S. Do you think that some welding codes deal with the base metal thickness essential variable in an odd or inexplicable way? Do you work with a welding code that we have not mentioned, and want to add to the topic? Please share your stories, opinions and insights regarding today's topic, directly on the e-zine page on the WelderDestiny website. Click here to add your contribution directly to the WelderDestiny website... P.P.S If you know anybody that you believe could benefit from The WelderDestiny Compass, please forward it to them. If this e-zine was forwarded to you, and you are interested in receiving our future editions, please visit the WelderDestiny.com website and enter your e-mail details into the subscription box. It is a big red box on the home page, so you can't really miss it. - I hope! Click here for the best version of The WelderDestiny Compass back-issues... |

| Back to Back Issues Page |